Production of high-precision optics in large quantities (PGM)

Precision molding (PGM) is an effective production method for optical lenses in mass production. We use this process to manufacture a wide range of precision optical elements. Our focus is on micro-optics. PGM is an abbreviation of Precision Glass Molding. In this process, an optical element made of glass is formed into its desired shape. The lensdoes not require any further process steps that change the optical surface. A glass blank is heated together with the mold to a temperature between transformation temperature and softening temperature and pressed into the mold to form a lens. In the process, the glass takes on the shape of the mold.

Customised and standard aspheres

Compared to conventional methods of producing glass optics, where the blank has to be ground and polished several times, the precision molding process does not require such time-consuming material-removing process steps. The material is placed as a blank between the tools and heated together with them to the molding temperature (isothermal molding). The molds then move towards each other and form the glass into a lens with a previously defined force. The tool and the glass are then cooled down again together and the process can start again. No further post-processing is necessary. The PGM process is particularly suitable for the economical production of large quantities.

Highest quality and precision

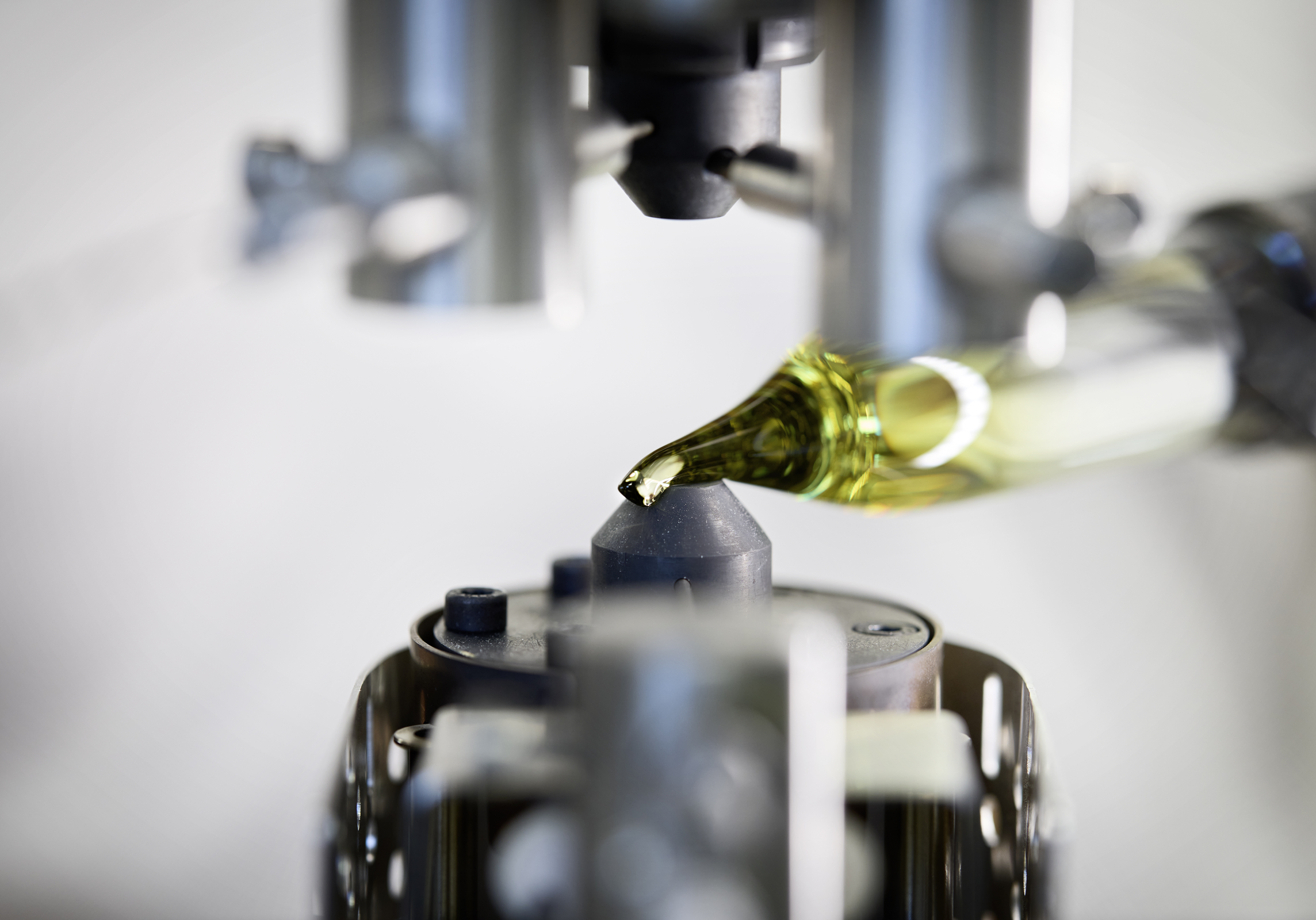

With the Rod Glass Moulding (RGM) process, which we have developed and optimised ourselves, we can produce optical components from glass very cost-effectively in a single moulding process step. RGM is an abbreviation of Rod Glass Molding. Thanks to the high process flexibility, we can produce complex glass optics and even microstructured surfaces in a variety of geometries, e.g. aspheres or segmented optics. In doing so, we achieve the highest quality and precision, otherwise only known from precision molding. Due to the particularly short cycle times, in fractions of minutes, the process is ideally suited for series production of quantities from a few 100 pieces up to many 100,000 pieces. Due to its extremely short process times, the rod molding process is particularly economical.

Production at high speed

The machines for the rod molding process are a proprietary development of GD Optics' own mechanical engineering department and enable fast and high-quality production.

Intelligent process optimisation

The temperature distribution and the entire process are optimised so that a very good surface quality can be achieved despite the fast forming process. Especially for certain shapes such as diffraction-limited aspheres.

Only a few steps to the finished lens

Thanks to our process, lenses in various geometries, whether round or angular or in other complex shapes, can be produced in a very short time. These can then be coated with optical layers if desired.

Quality management according to DIN/ISO 9001

We create production technologies and improve processes to offer the highest possible security - in terms of quality, homogeneity, timing and quantities.

About us

GD Optics is one of the leading international suppliers for the development and production of innovative and high-precision optical components for high-tech applications. We fully cover the entire process chain up to the production and packaging of the optics.

Worldwide microlenses solutions

GD Optical Competence GmbH

Zur Dornheck 24 | 35764 Sinn

Germany

Telephone: + 49 2772 5744 - 0

E-Mail: info@gdoptics.de

© GD Optical Competence GmbH 2021 | All rights reserved