Thanks to our many years of experience in the realisation of individual requirements, we are able to develop innovative and cost-efficient solutions just in time. The entire development process is centrally controlled by GD Optics' quality management - from complex calculations to the production of precision optics.

High-intensity range significantly more cost-effective

Lenses that are produced in large quantities from plastic using a low-cost injection moulding technique usually have very low laser damage thresholds. For this reason, many optics in the field of laser material processing are produced as diffractive elements from glass by means of lithography, which is associated with high costs.

GD Optics has developed a solution with its precise moulding process that allows beam shaping elements to be produced in higher quantities much more economically than with lithographic processes. Our innovative glass moulding process is suitable for the production of both refractive and diffractive optical elements.

Customised, efficient and high quality

By using aspheres in optical systems, particularly compact and lightweight designs can be realised because the number of lenses used can be reduced. Precisely molded aspheres are our speciality. We manufacture customised and standard aspheres with a diameter of up to 30 mm.

About us

GD Optics is one of the leading international suppliers for the development and production of innovative and high-precision optical components for high-tech applications. We fully cover the entire process chain up to the production and packaging of the optics.

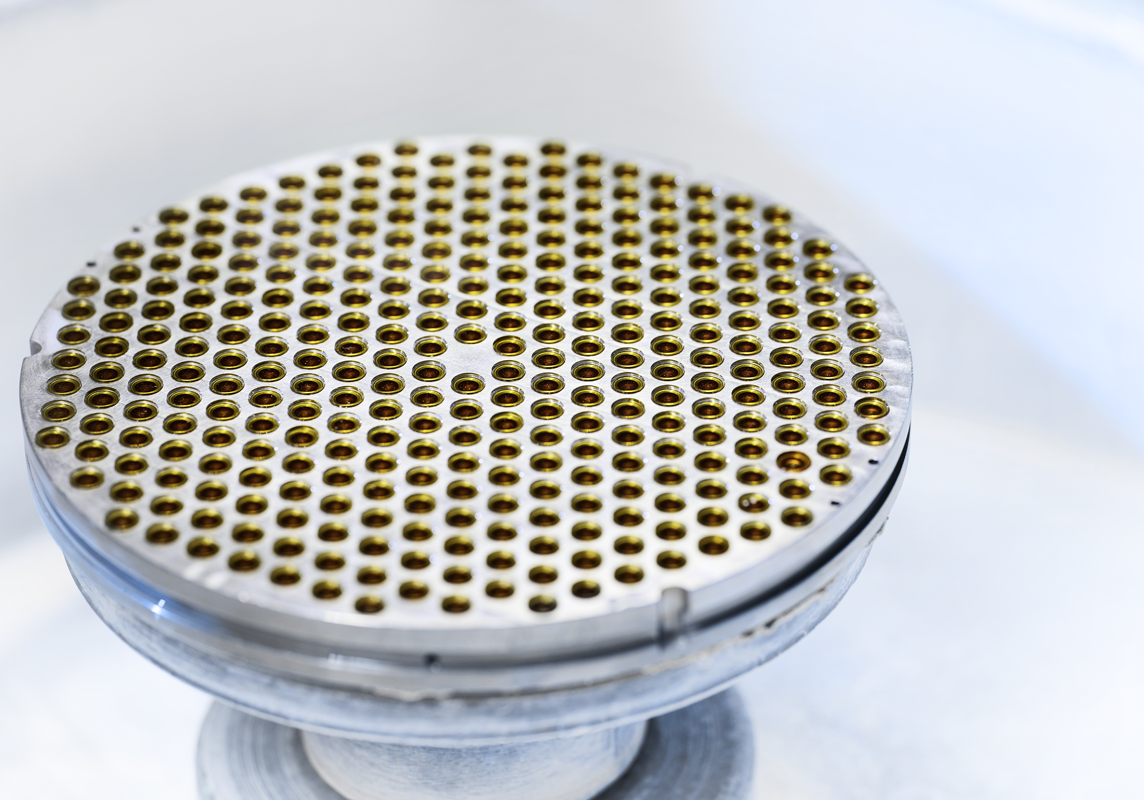

Worldwide microlenses solutions

GD Optical Competence GmbH

Zur Dornheck 24 | 35764 Sinn

Germany

Telephone: + 49 2772 5744 - 0

E-Mail: info@gdoptics.de

© GD Optical Competence GmbH 2021 | All rights reserved